| Model No. | Size | Quantity | Step(mm) | Model No | Size(mm) | Quantity | Step(mm) | Model No. | Size(mm) | Quantity | Step(mm) | |||

| 1201-1 | 1.01-2.00 | 100 | 0.01 | 1201-39 | 2.00-2.50 | 51 | 0.01 | 1201-77 | 1.000-1.015 | 51 | 0.005 | |||

| 1201-2 | 2.01-3.00 | 100 | 0.01 | 1201-40 | 2.50-3.00 | 51 | 0.01 | 1201-78 | Â 1.250-1.265 | 51 | 0.005 | |||

| 1201-3 | 3.01-4.00 | 100 | 0.01 | 1201-41 | 3.00-3.50 | 51 | 0.01 | 1201-79 | 1.500-1.515 | 51 | 0.005 | |||

| 1201-4 | 4.01-5.00 | 100 | 0.01 | 1201-42 | Â 3.50-4.00 | 51 | 0.01 | 1201-80 | 1.750-1.765 | 51 | 0.005 | |||

| 1201-5 | 5.01-6.00 | 100 | 0.01 | 1201-43 | 4.00-4.50 | 51 | 0.01 | 1201-81 | 2.000-2.015 | 51 | 0.005 | |||

| 1201-6 | 6.01-7.0 | 100 | 0.01 | 1201-44 | 4.50-5.00 | 51 | 0.01 | 1201-82 | 2.250-2.265 | 51 | 0.005 | |||

| 1201-7 | 7.01-8.00 | 100 | 0.01 | 1201-45 | 5.00-5.02 | 51 | 0.01 | 1201-83 | 2.500-2.515 | 51 | 0.005 | |||

| 1201-8 | 8.01-9.00 | 100 | 0.01 | 1201-46 | 5.50-5.52 | 51 | 0.01 | 1201-84 | 2.750-2.765 | 51 | 0.005 | |||

| 1201-9 | 9.01-10.00 | 100 | 0.01 | 1201-47 | 6.00-6.02 | 51 | 0.01 | 1201-85 | 3.000-3.015 | 51 | 0.005 | |||

| 1201-10 | 1.00-5.00 | 41 | 0.01 | 1201-48 | Â 6.50-6.52 | 51 | 0.01 | 1201-86 | 3.250-3.265 | 51 | 0.005 | |||

| 1201-11 | 5.00-10.00 | 51 | 0.01 | 1201-49 | 7.00-7.02 | 51 | 0.01 | 1201-87 | 3.500-3.515 | 51 | 0.005 | |||

| 1201-12 | 10.00-15.00 | 51 | 0.01 | 1201-50 | 7.50-7.52 | 51 | 0.01 | 1201-88 | 3.750-3.765 | 51 | 0.005 | |||

| 1201-13 | 15.00-20.00 | 51 | 0.01 | 1201-51 | 8.00-8.02 | 51 | 0.01 | 1201-89 | 4.000-4.015 | 51 | 0.005 | |||

| 1201-14 | Â 1.00-10.00 | Â 91 | 0.01 | 1201-52 | 8.50-8.52 | 51 | 0.01 | 1201-90 | 4.250-4.265 | 51 | 0.005 | |||

| 1201-15 | 1.00-5.00 | 81 | 0.05 | 1201-53 | 9.00-9.02 | 51 | 0.01 | 1201-91 | 4.500-4.515 | 51 | 0.005 | |||

| 1201-16 | 0.505-1.005 | 51 | 0.01 | 1201-54 | 9.50-9.52 | 51 | 0.01 | 1201-92 | 4.750-4.765 | 51 | 0.005 | |||

| 1201-17 | 1.005-2.005 | 51 | 0.01 | 1201-55 | 10.00-10.02 | 51 | 0.01 | 1201-93 | 5.000-5.015 | 51 | 0.005 | |||

| 1201-18 | Â 1.505-2.005 | Â 51 | 0.01 | 1201-56 | 10.50-10.52 | 51 | 0.01 | 1201-94 | Â 5.250-5.265 | 51 | 0.005 | |||

| 1201-19 | 2.005-2.505 | 51 | 0.01 | 1201-57 | 11.00-11.02 | 51 | 0.01 | 1201-95 | 5.500-5.515 | 51 | 0.005 | |||

| 1201-20 | 2.505-3.005 | 51 | 0.01 | 1201-58 | 11.50-11.52 | 51 | 0.01 | 1201-96 | 5.750-5.765 | 51 | 0.005 | |||

| 1201-21 | 3.005-3.505 | 51 | 0.01 | 1201-59 | 12.00-12.02 | 51 | 0.01 | 1201-97 | 6.000-6.015 | 51 | 0.005 | |||

| 1201-22 | 3.505-3.525 | 51 | 0.01 | 1201-60 | 12.50-12.52 | 51 | 0.01 | 1201-98 | 6.250-6.265 | 51 | 0.005 | |||

| 1201-23 | 4.005-4.025 | 51 | 0.01 | 1201-61 | 13.00-13.02 | 51 | 0.01 | 1201-99 | 6.500-6.515 | 51 | 0.005 | |||

| 1201-24 | Â 4.505-4.525 | Â 51 | 0.01 | 1201-62 | 13.50-13.52 | 51 | 0.01 | 1201-100 | Â 6.750-6.765 | 51 | 0.005 | |||

| 1201-25 | 5.005-5.025 | 51 | 0.01 | 1201-63 | 14.00-14.02 | 51 | 0.01 | 1201-101 | 7.000-7.015 | 51 | 0.005 | |||

| 1201-26 | Â 5.505-5.525 | 51 | 0.01 | 1201-64 | Â 14.50-14.52 | 51 | 0.01 | 1201-102 | Â 7.250-7.265 | 51 | 0.005 | |||

| 1201-27 | 6.005-6.025 | 51 | 0.01 | 1201-65 | 15.00-15.02 | 51 | 0.01 | 1201-103 | 7.500-7.515 | 51 | 0.005 | |||

| 1201-28 | 6.505-6.525 | 51 | 0.01 | 1201-66 | 15.50-15.52 | 51 | 0.01 | 1201-104 | 7.750-7.765 | 51 | 0.005 | |||

| 1201-29 | 7.005-7.025 | 51 | 0.01 | 1201-67 | 16.00-16.02 | 51 | 0.01 | 1201-105 | 8.000-8.015 | 51 | 0.005 | |||

| 1201-30 | 7.505-7.525 | 51 | 0.01 | 1201-68 | Â 16.5-16.52 | 51 | 0.01 | 1201-106 | Â 8.250-8.265 | 51 | 0.005 | |||

| 1201-31 | 8.005-8.025 | 51 | 0.01 | 1201-69 | 17.00-17.02 | 51 | 0.01 | 1201-107 | 8.500-8.515 | 51 | 0.005 | |||

| 1201-32 | 8.505-8.525 | 51 | 0.01 | 1201-70 | 17.5-17.52 | 51 | 0.01 | 1201-108 | 8.750-8.765 | 51 | 0.005 | |||

| 1201-33 | 9.005-9.025 | 51 | 0.01 | 1201-71 | 18.00-18.02 | 51 | 0.01 | 1201-109 | 9.000-9.015 | 51 | 0.005 | |||

| 1201-34 | Â 9.505-9.525 | Â 51 | 0.01 | 1201-72 | 18.50-18.52 | 51 | 0.01 | 1201-110 | 9.250-9.265 | 51 | 0.005 | |||

| 1201-35 | 0.20-0.22 | 31 | 0.01 | 1201-73 | 19.00-19.02 | 51 | 0.01 | 1201-111 | 9.500-9.515 | 51 | 0.005 | |||

| 1201-36 | 0.50-1.00 | Â 51 | 0.01 | 1201-74 | 19.5-20.00 | 51 | 0.01 | 1201-112 | Â 9.750-9.765 | 51 | 0.005 | |||

| 1201-37 | 1.00-1.50 | 51 | 0.01 | 1201-75 | 0.500-0.750 | 51 | 0.005 | |||||||

| 1201-38 | Â Â 1.50-2.00 | 51 | 0.01 | 1201-76 | 0.750-0.765 | 51 | 0.005 | |||||||

Product Description

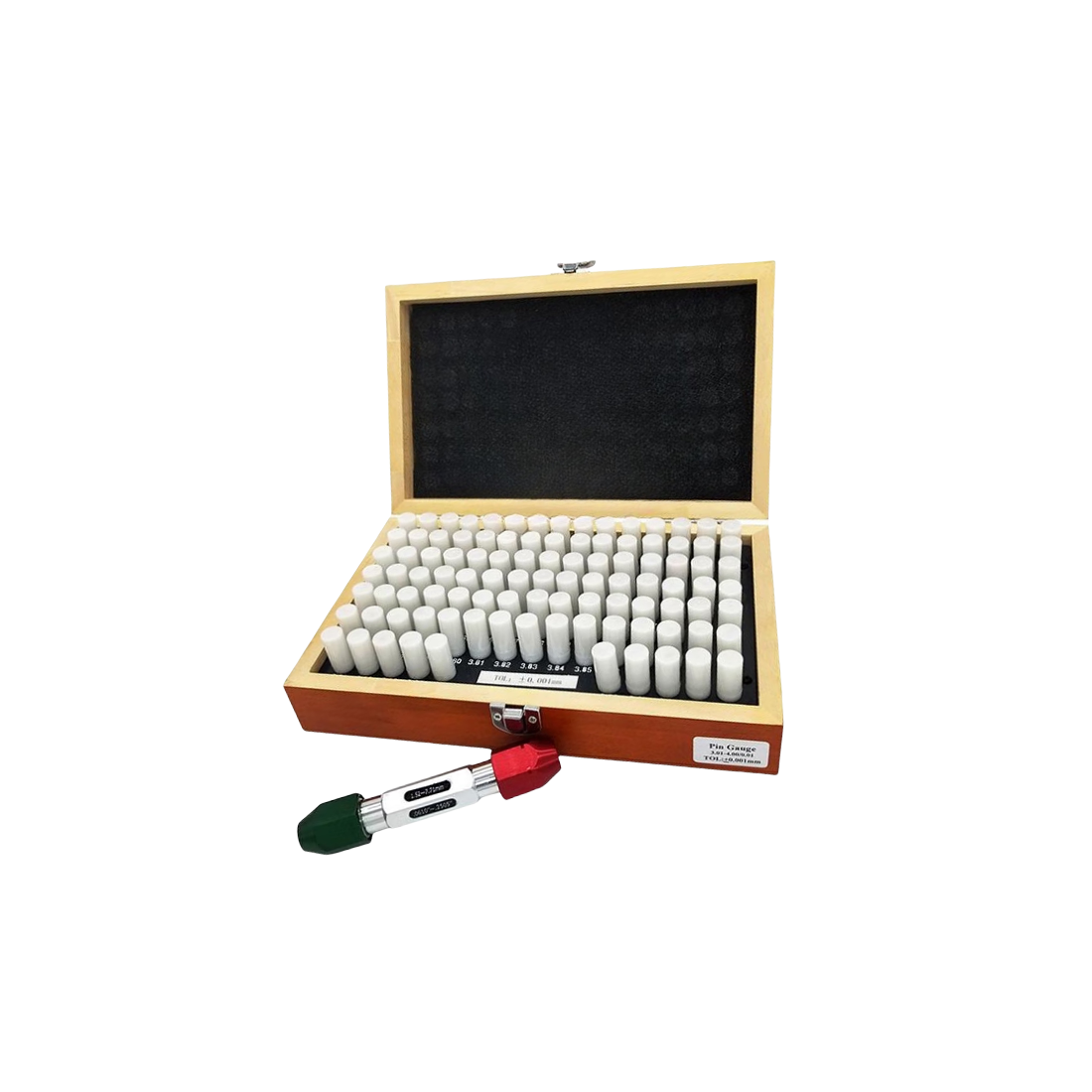

Professional Precision Pin Gauge Set for Hole Measurement and Inspection

Our high-precision pin gauge sets are engineered for accurate hole diameter measurement, bushing inspection, and wear part verification. Manufactured from hardened steel with HRc60-62 hardness and uniform 2-inch length, these gauges feature a smooth 10-microinch finish for precise measurements in mechanical workshops, manufacturing, and quality control applications.

Key Features & Benefits:

• High Precision Manufacturing – 0.001″ increments for accurate diameter measurement from 0.011″ to 1.000″

• Exceptional Hardness – HRc60-62 hardened steel construction ensures long-term durability and wear resistance

• Uniform Design – Consistent 2-inch length with smooth 10-microinch surface finish for reliable measurements

• Complete Set Options – Multiple sets available covering entire range from 0.011″ to 1.000″

• Professional Applications – Ideal for go/no-go gauging, hole position checking, and distance measurement

• Quality Assurance – Perfect for quality control, manufacturing inspection, and mechanical workshops

Available Set Configurations:

• M0 Set: 0.011-0.060 inch

• M1 Set: 0.061-0.250 inch

• M1A Set: 0.061-0.250 inch (Aluminum Case)

• M2 Set: 0.251-0.500 inch

• M3 Set: 0.501-0.625 inch

• M4 Set: 0.626-0.750 inch

• M5 Set: 0.751-0.832 inch

• M6 Set: 0.833-0.916 inch

• M7 Set: 0.917-1.000 inch

Technical Specifications:

• Material: Hardened Steel

• Hardness: HRc60-62

• Length: 2 inches (uniform)

• Surface Finish: 10 microinch or better

• Increment: 0.001″

• Range: 0.011″ to 1.000″

• Applications: Hole diameter measurement, alignment checking, go/no-go gauging

Ideal Applications:

-

Quality control and inspection departments

-

Machine shops and manufacturing facilities

-

Automotive and aerospace industries

-

Maintenance and repair workshops

-

Tool and die making

-

Research and development laboratories

Why Choose Our Pin Gauge Sets?

These professional-grade pin gauges provide reliable and accurate measurements for critical inspection applications. The hardened steel construction and precise manufacturing ensure consistent performance, while the complete range of sets covers all measurement requirements from 0.011″ to 1.000″. Perfect for verifying hole sizes, checking part wear, and ensuring manufacturing quality standards.

[Request Catalog] for complete technical specifications or [Contact Us] for custom set configurations and volume pricing.